The powerful controller for system solutions in the manufacturing and process industries

Description

There is a graded range of CPUs from the entry-level CPU right up to the high-performance CPU for configuring the controller. All CPUs control large quantity structures; several CPUs can work together in a multicomputing configuration to boost performance. Thanks to their high processing speed and deterministic response times. the CPUs enable short machine cycle times.

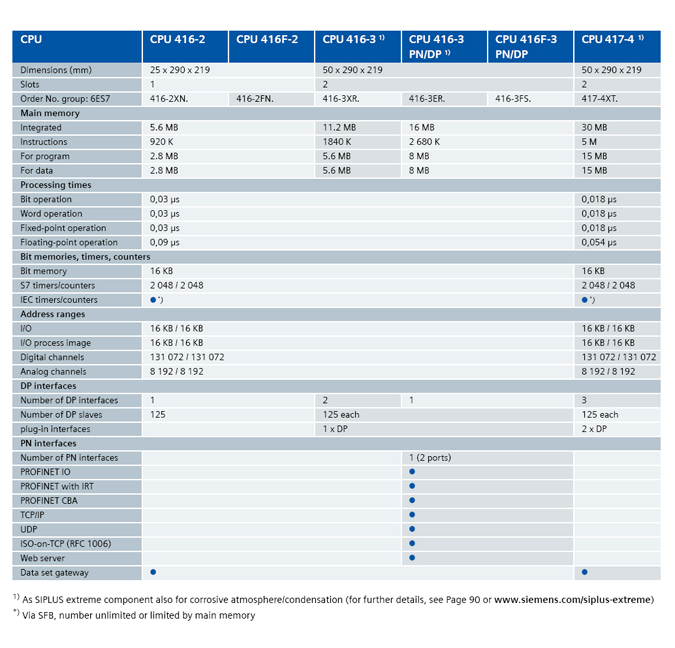

The different CPUs are distinguished by, for example, work memory, address range, number of connections and execution time. As well as the standard CPUs, there are also two failsafe and three fault-tolerant CPUs available.

Benefits

- The power of the S7-400 is scalable thanks to a graded range of CPUs; the capacity for I/O is almost unlimited.

- The power reserves of the CPUs enable new functions to be integrated without further hardware investment, eg. processing of quality data, user-friendly diagnosis, integration into higher-level MES solutions or high-speed communication via bus systems.

- The S7-400 can be structured in a modular way; there is a widely varied range of modules available both for centralized configuration of the distributed structures. This results in very cost-effective spare parts handling.

- The configuration of the distributed I/O of the S7-400 can be modified during operation (Configuration in Run). In addition signal modules can be removed and inserted while live (hot swapping). This makes it very easy to expand the system or replace modules in the event of a faults.

- The storage of the complete project data including symbols and comments on the CPU simplifies service and maintenance calls.

- Safety engineering and standard automation can be integrated into a single S7-400 controller; plant availability can be increased through the redundant structure of the S7-400.

- Many of the S7-400 components are also available in a SIPLUS version for external environmental conditions, eg. extended temperature range (-25°C…+70°C) and for use where there is aggressive atmosphere/condensation.

- The high-speed backplane bus of S7-400 ensures efficient linking of central I/O modules

Application

- The S7-400 is especially suitable for data-intensive tasks in the process industry. High processing speeds and deterministic response times guarantee short machine cycle times on high-speed machines in the manufacturing industry.

- The S7-400 is used preferably to coordinate overall plants and to control lower-level systems. This is guaranteed by the high communication power and the integral interfaces.

- Many of the S7-400 components are also available in a SIPLUS version for extreme environmental conditions.

S7-400 finds successful application here:

- Automotive industry

- Standard mechanical equipment manufacture including custome mechanical equipment manufacture

- Warehousing systems

- Building engineering

- Steel industry

- Power generation and distribution

- Paper and printing industrues

- Wood working

- Textile manufacture

- Pharmaceuticals

- Food and beverages industries

- Process engineering, eg. water and waste water utilities

- Chemical industry and petrochemicals